Features of PE warning protection board

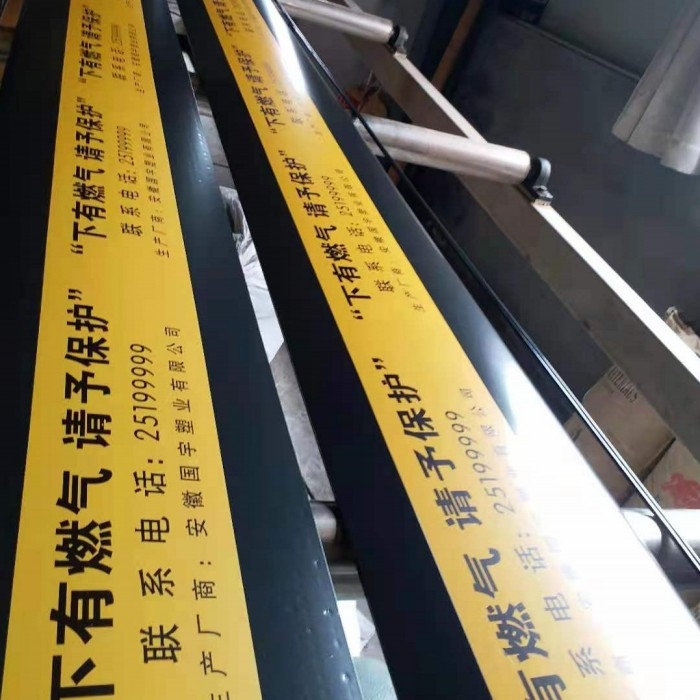

PE warning protection board (also known as; underground pipeline PE warning protection board Plastic protection board) uses HDPE high-density polyethylene\LDPE low-density polyethylene as the main raw material, and the protection board is covered with double-layer 0PP color printing film, so that the warning font will be stored for a long time and will not be destroyed by nature, which is effective for PE gas pipes Warning and protection.

Feature

1. Long service life;

2. High tensile strength, good flexibility, strong shock resistance, distortion resistance, and strong resistance to deformation;

3. Cold-resistant -60°C, the plate will not burst when facing;

4. High temperature resistance 75"C, the plate is not deformed;

5. Excellent corrosion resistance;

6. Strong impact resistance (no breakage under frontal impact within 1000 kg);

PE warning protection board product description

It is suitable for the protection and warning of various gas pipelines, communication cables, power facilities, power supply lines and communication optical fibers, municipal engineering networks and communication pipeline engineering, etc. It is a protection board with relatively good performance. This product has been applied in thousands of underground pipeline units in our country! Its effect and effect are very obvious, and it has been well received by the market and customers. Among them, thin plates are mostly used for pipeline construction in living quarters, and thick plates are used for pipeline construction in municipal engineering.

The protection board is installed on the buried polyethylene (PE) gas pipeline laid by the trench excavation method. The plastic protection board should be installed for protection. The protection board is laid about 500mm directly above the pipeline, and the side with the warning sign printed on the plastic board is up. Laying. The width of the protective plate should be greater than the diameter of the pipe to be protected. When the width of the protective plate is insufficient, the connection can be made by overlapping. The overlapping width should not be less than one-third of the plate width. The protective plate should be lapped by punching and strapping. Fix it. When the pipeline changes the laying direction and the three-way branch, the protective plate should change the direction. The plate-shaped protective plate adopts the plastic connecting bolt to directly turn or the three-way connection. When the coiled protective plate is laid, it can be cut and turned before connecting, and bundled with plastic With effective connection of the protection board